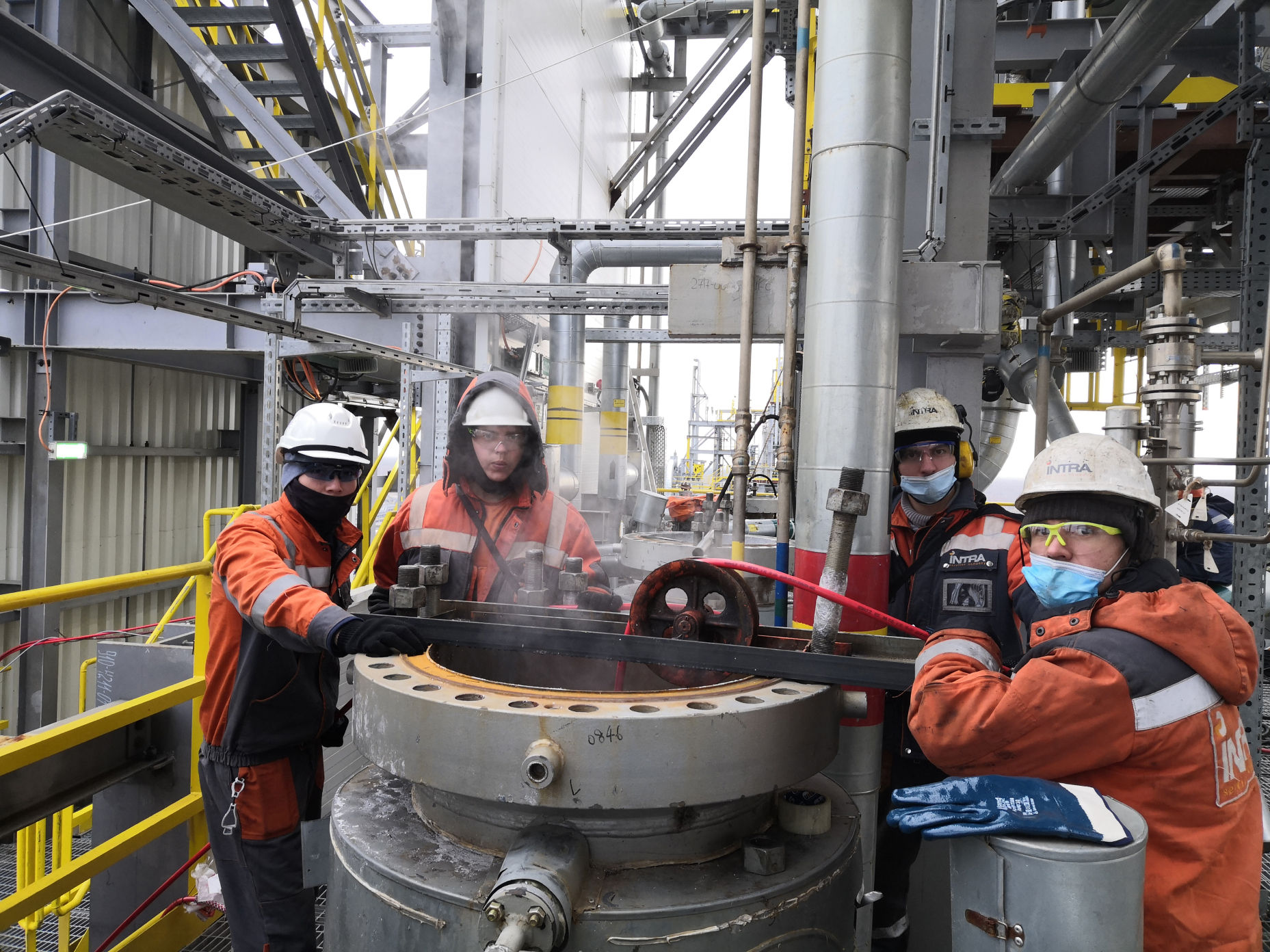

PIPELINE AND EQUIPMENT CLEANING

Pressure washing

Internal surface cleaning involves insertion of high-pressure hose into the inner cavity of equipment to be cleaned (tube) by means of rotation of the spray nozzle (pulverizer) and directed jet of water under high pressure up to 2,800 bar, whereupon depositions on pipe walls (heat exchangers, pipelines) are destroyed and washed out.

UHP (ULTRA HIGH PRESSURE) — ULTRA HIGH PRESSURE WATERJET TECHNOLOGY

ADVANTAGES

- Work performance in hard-to-reach areas

- Safety of work performance

- Mobility and efficiency of work performance, arrival at equipment location sites in case of emergency

- Top-degree cleaning of hard-to-reach areas along with chemical methods

- Reduced repair time

- Eco-friendliness

HYDROCHEMICAL CLEANING

Cleaning of inner surfaces fr om scale-corrosive deposits by mixing chemical substances and water in certain proportions, special technical detergents, mineral or organic acids with special additives fed to the equipment or heat exchanger pipes under high pressure.

ADVANTAGES

- Penetrating power of technical detergents ensures quick dissolution of deposits without affecting finning material, following which dissolved deposits are washed off by a high-pressure washer (up to 2,800 bar)

- Working at any elevation spot

CHEMICAL CLEANING

Cleaning is performed by circulating technical detergents in a closed loop under a certain temperature and pressure in compliance with cleaning methodology for at least 24 hours. Technical detergents may consist of several components. The choice of composition, proportions, concentrations of components depends on the particular task, as well as the developed formulation and cleaning technique.

ADVANTAGES

- Reduced repair time

- Reduced period of installation works

- Increased time between repairs

- No unreasonable repairs

- Reduction in amounts of spare parts ordering and optimized order schedules

HYDROCHEMICAL CLEANING

Basic cleaning method for process equipment containing hard deposits and inorganic compounds in oil refining, petrochemical and other industries.

ADVANTAGES

- Water supply to the tool operation area results in considerable increase in efficiency of cleaning pipes, in increased longevity of equipment

- 100% cleaning of pipes without damage to their walls

- Cleaning speed and reliability

TANK AND RESERVOIR CLEANING

TECHNOLOGY

- Preparation of equipment for transfer of technological residue of commercial oil product to another tank to the minimum level

- Pumping off bottom sediments of the tank by TKM-629 vehicle (vacuum plant). While pumping off, deposits remain on the walls of the tank, which must be steamed for 24 hours in order to soften the deposits and make them flow down to the tank bottom

- Tank degassing to the values of maximum permissible explosive concentration

- Washing of the tank by means of high-pressure pump and chemical reagents

SCOPE OF APPLICATION

- Keeping the tank in an operable condition, when preparing for repairs and hot work

- The tank cleaning technology ensures reduction of hydrocarbon vapours concentration to the values of maximum permissible concentration and lower concentration lim it, as well as cleaning of tank surfaces from deposits to maximum permissible fire load

- Feasibility of oil product change, repair work performance